- Home

- Item Weight

- 1.32lb. (5)

- 1.6 Pounds (4)

- 10 Pounds (10)

- 10.63 Pounds (5)

- 12 Pounds (4)

- 12.57 Pounds (3)

- 2 Pounds (5)

- 3.3 Pounds (11)

- 33.2 Pounds (2)

- 3824g / 8.4lb (9)

- 4950g / 10.9lb (4)

- 5 Pounds (12)

- 5.39 Pounds (3)

- 5.64 Pounds (3)

- 7.5 Pounds (5)

- 7.6 Pounds (6)

- 8 Kilograms (5)

- 8.8 Pounds (8)

- 9 Pounds (22)

- 9.9 Pounds (11)

- ... (3883)

- Material

- Maximum Height

- 146 Centimeters (4)

- 155cm / 61inch (13)

- 160 Centimeters (6)

- 1600mm / 48in (4)

- 1645mm / 49.3in (3)

- 165cm (10)

- 170 Centimeters (8)

- 183 Centimeters (14)

- 185 Centimeters (11)

- 188cm (10)

- 57.5 (3)

- 61\ (8)

- 62 Inches (7)

- 70 7 / 8\ (4)

- 70.8 Inches (4)

- 72 Inches (12)

- 72.7 Inches (6)

- 74 Hundredths-inches (9)

- 75 In (4)

- 75.6'' (5)

- ... (3875)

- Minimum Height

- Part Number

- Weight Limit

CNC Router Mill Industrial Grade, with DSP, Steel Gantry Professional Heavy Duty

But we will make out okay in the long run since we got these machines at this price because we ordered so many and only needed less than half of what we ordered. Because of the size and weight... And only in the Continental United States. I know this seems like a lot to read... But it will be worth your time to read it all.

There is valuable information here that I wish I knew at the beginning of our own CNC machine journey. So benefit from our experience and read carefully.

These are custom made professional grade machines designed and professionally built for extreme precision, registration repeatability, heavy duty cutting, high volume runs and output and KISS ease of use. In short, if you want to make professional parts and products but don't want to spend months or years learning how to be a machinist, you need a professional industrial grade machine that can do what you need but is easy to learn and work with....

A machine like this one. Whether it's light weight plastic, to wood, to G10 to brass, to titanium, all the way to steel... This machine can do it all. The differences between hobby grade machines and professional machines are many. Professional machines are heavier, made from thicker stronger materials, use precision ground direct drive ballscrews and linear guide rails on all axes, have stronger spindles and drive motors, and more often than not, have their own onboard operating control system so no additional computer or software like Mach 3 or 4 (for example) is needed.Important information about this Machine and some about CNC machining in general as well. An integrated DSP control system on the control box, already programmed, calibrated and setup for this particular machine, makes it unneccessary to use a separate computer or software such as Mach 3 or 4 to operate.

Simply plug in a TF card (micro SD) containing your Gcode in. Tab or other common format... Turn on the machine and the spindle, push the run button on the spindle's vfd control...

Then turn the control knob so that the blinking reset box is highlighted, push the control knob or "OK" button... Jog bit tip to your zero... Set zero with the button that looks like a crossed out C...Find your file you want to use... Push the control knob while on your selected file, twice, then the run button right next to it....

And voila', you're making your first piece on the machine. Not only is the integrated DSP much easier to use than pretty much any other operating system I've ever used, it's also more stable. We've used one for up to 6 weeks straight with no resets or turning off the machine, and it's never faulted... Which is quite different than Mach 3 and the like, which seems to need resetting pretty much every 24 hours on every computer system I've used it on. The Machine is about twice as heavy as most other 6040 type machines, weighing almost 400 lbs.. And that's with an empty water basin... Weighs a lot more when full. More weight equals less vibration, better stability and more inherent precision.Gantry and support structure is made from heavy, almost 5/8 thick, steel for heavy industrial use. Very heavy and very strong, yet the machine will fit through a standard doorway... Heavy duty, high precision direct drive ballscrews and precision ground linear guide rails are used on all three axes which means no twist, flex or bowing like you get on hobby grade machines.

There are strong NEMA 34 (1700 oz/inch) industrial grade Closed Loop stepper motors on all three axes. Closed loop means you don't get the zero point drift like you get with open loop hobby machines.. With a hobby machine, if you drill a registration hole at your zero point, after using it for a decent length of time and you want the machine to go to zero, your bit will not line up exactly on the registration hole... Depending on how much time, and hardness of material being cut the lineup may be off by more than a millimeter. Whereas a Closed loop system will be dead on center of hole after any amount of time no matter how large the workpiece or how tough the material being worked on. Open loop systems do not have an internal verification system (feedback loop) to know how far or how many steps were actually taken, they basically go by amount of power used equals a certain number of steps, not really measuring actual distance moved... So if cutting into hard materials, an open loop system will typically miss or lose steps because it expended the correct amount of power to go a certain amount of steps, but it actually did not because the material is harder and requires more power to go the same distance as cutting a softer material... In other words, it may have moved the correct distance if cutting a light wood or plastic, but if cutting something like aluminum or G10, it takes more power to go the right amount of steps and open loop systems don't have a way to compensate for that. As the step count error accummulates over the course of a project, it will give distorted results... Like elongated holes, or instead of straight sides they angle and step down and so forth. The harder the material, and more time/lines of code, the greater the distortion.... Most people are fine with this, as it's usually not that bad when working with light materials. But if you want truly professional results and have high standards, this is not acceptable. With a closed loop system, like this machine has, an incorporated feedback loop verifies the correct amount of steps (regardless of power used) have been taken for every called for action in your Gcode, thus, as it works even on the hardest of materials, it correctly and continuously counts it's steps and makes sure it goes the proper amount of steps/distance called for in the gcode... So at the end of your project, when you tell it to go to the registration hole, it will be dead center of it. This is especially useful when doing 3D work on flat board material, because when you flip the piece using a closed loop system, no compensation is required...The registration hole is exactly where your zero needs to be. As a result of the step count always being correct, holes will be the right shape, straight sides will be straight and flat, no distortion. Closed loop systems are the real secret to getting professional results.

On this machine, a water holding stainless steel basin sink with a drain in back completely encloses a thick professional grade bed that can use common 1/4 Tbolts and hold down clamps. Clampable bed size is 750mm X 450mm with a working area, where spindle can cut on the X and Y axis, at 400mm X 600mm (15.75" X 23.75"). Bed is large enough to comfortably clamp a 16" X 24" workpiece to it. Spindle can travel/cut 100mm - 150mm (4"- 6") in the Z axis depending on length of bit and position of spindle in sleeve.The deep basin allows for underwater cutting... Meaning very quiet cutting operation and no dust if cutting glass fiber type boards or stone, and automatic cooling and lubrication to assist in cutting all sorts of metals.

Of course if you don't want to cut underwater, there is a water cooling pump and adjustable spray nozzle included as well, the sink will contain the water from that or excess water can be drained away, either way. And of course you don't have to use that either, if you don't want to cut dustless, like if cutting a wooden piece...

In which case, if you want to, you can hook up your air compressor and blow the chips away instead of using water. Another very handy thing that is different about this machine from almost every other one in its class is, this one was special ordered so that it is wired to use 110v common household current.All you need is one dedicated outlet to run the machine and the water pump for cooling the spindle. No need to call an Electrician as 220v is not used or needed...

This one thing alone, makes it one of the most useful and versatile machines available anywhere, as it can be used almost anywhere! Spindle is a water cooled three horsepower with four stabilization bearings instead of the two many hobby grade machines use.

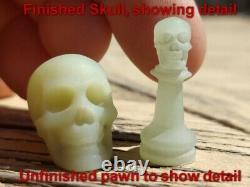

Collar size is er20 for more stable spring collet inserts in larger sizes for larger diameter bits. Spindle runs up to 24,000 RPM, rated at less than 0.003mm runout/chatter... When you can cut a skull from a grain of rice, and the teeth are all showing and the septum inside the nose cavity is showing...

That is some REAL precision, and that's just a simple real world example of what this machine is capable of. In Short, all CNC machines are not created equal.. If all you need is to cut 3D relief family crest panels or signs out of soft wood, then a even a hobby grade CNC router will be fine. But if you want to do something in heavier more dense materials like aluminum, brass, copper, G10, micarta, carbon fiber or even mild steel, and you want repeatable, consistent results...

Then you're going to need a professional level machine. Only professional, heavy duty, machines with big spindles and closed loop systems can give you the results you're looking for if you want truly professional results. A little about us and our CNC machine journey. For the last 12 years we've been running our own business making all sorts of items... Everything from pistol and knife grips, machine parts, chess sets, on to our main product, Slingshots, and all sorts of products and things in between. In making all these things it was found that using CNC mills/routers are some of, if not the most, useful and productive tools you can use. I'll just tell what we actually get with no fluff or BS.... You can watch many videos on youtube that say you can...But let's try to stay in the realm of reality and what actually can and does happen. I'm sure there are some niche markets you can get into that may pay as much as these guys are saying... But as soon as others know about it... Well you know the rest, you're not an idiot. Using a decent CNC machine to do all the difficult intricate, time consuming shaping and carving, with minimal hand finishing, so all that's needed is to take down the part support tabs and the occasional center line...

Plus since we're doing it all ourselves we're not easily deemed "non essential" and go for weeks or months without a paycheck hoping the government will help us out. In an uncertain world, it's the closest thing to a certain paycheck. Like most people and businesses, we started on the cheap... Looking for the least expensive options and ways to get what we thought was what we wanted...

In fact our first machine was from Carbide3D, a Nomad 883 then bought a custom Shapeoko... And we thought they were great, and in fact we made quite a bit with them. But we just couldn't get quite the perfect kind of results we were after.

So even though we liked the machines we still looked, studied and listened.. The only real downsides were, the machines we used actually had a lot of limitations... Which kind of gets expensive because the computer always seems to have little quirks and of course Mach 3 seems like it can't run for longer than 24 hours without crashing.. So some projects have to be restarted and some are actually ruined. Then there's the X and Y drift...When you run a longer routine the open loop machines tended to lose their place, losing steps in their count. Over a period of time due to being open loop systems... The longer the program the more this type of machine error becomes.

Of course other problems such as not being able to efficiently cut and shape metals and stone also acted as limiting factors... The machines just weren't strong enough, flexxing and bowing were a problem when cutting stronger materials. Because those machines had all those limitations and many more...We contacted pretty much every major CNC machine "maker" in the USA we could find to see if they could make the ultimate dream machine for us... That's when I found out if I want the best product at the best price I really need to deal directly with the companies in China that do this sort of work..

And that is what we did. I happened to have some Asian contacts that most people don't have, and we utilized them. These machines were custom ordered from one of the highest rated CNC machine making companies in China to have everything we wished our machines had that we've been using for the last 5 or 6 years...To have everything we wanted and nothing we don't or never use. There was one major drawback...

And that was, if you want the machines at a more affordable price, you have to order a larger quantity than you actually need... And that's what we're doing now! We only need a maximum of 5-8 machines... So we're going to sell the rest.

This is a VERY good deal for the right person or people... You can be making products for sale almost immediately after that.

Take your future, make it what you want it to be. With just a little creativity and the will to make it happen, you can insulate your life against problems like we've already been experiencing recently in the world, and against the unknown and unforeseen as well. You will never be called "non essential" again! Video of it in action, carving a grain of rice! Video of how to use the DSP.

This item is in the category "Business & Industrial\CNC, Metalworking & Manufacturing\Woodworking Equipment\Routers". The seller is "pocket_predator" and is located in this country: US. This item can be shipped to United States.

- Brand: Unbranded

- Control: CNC

- Model Year: 2021

- Modification Description: Custom ordered Industrial Grade for Heavy Use

- Machine Type: 3 Axis Router Machine

- Power Source: Electric

- Custom Bundle: Yes

- Country/Region of Manufacture: China

- Modified Item: Yes